CNC Technology at work for you

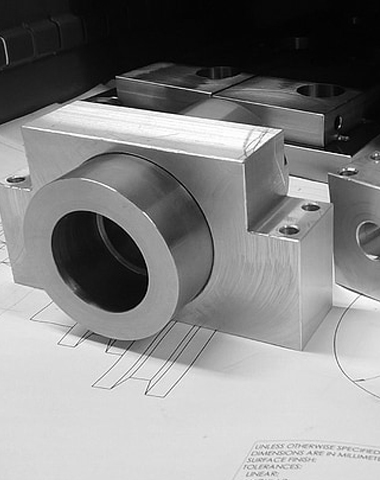

Excell Industries has made significant investments over the past few years in top-of-the-line new machinery, which puts us in the 5% of the nation’s capabilities. We are committed to investing in future technologies to advance our capabilities and meet our customers’ most demanding requirements. Our experience with OEM in the auto and heavy equipment industries allows us to identify and implement the precise machine tool solution necessary to achieve our standards and fulfill our customers requirements.

Our Services

With todays cutting edge machines, we are able to provide precision products in rapid time. Our 5 and 9-Axis CNC machines allow you peace of mind knowing each item is accurate and quality.

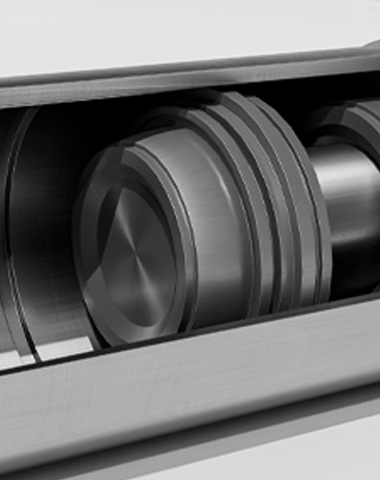

We specialize in the medium to high volume production of CNC machined components used in the fluid power industry. As well as the manufacturing of hydraulic and pneumatic cylinders for specific applications.

We have the machinery, the skilled personnel, and the experience needed to meet the production and quality requirements of critical components utilized in the aerospace industry as a sub‐contractor or prime contractor.

Are you looking for a manufacturing partner to provide CNC Machining and Engineering Support that provides an alternative solution for your specific application? Give us a call to inquire about our unique capabilities.

We have some of the best and brightest engineers, backed by years of experience ready to assist in creating the perfect solution for your needs. From aerospace to hydraulics we have you covered.

Skiving

Excell Industries uses the Sierra USA®, the World’s Fastest Skiving & Roller Burnishing machine. With speeds of 4 meters per minute (158” per minute), an 80mm (3.15ʺ) I.D. tube x 1M (39.4ʺ) part length and 2mm (0.040ʺ) stock removal can be skived and roller burnished with one forward pass in 30 seconds. Finishing the inside diameter of a hydraulic cylinder with the most accurate tolerances in the industry will guarantee our customers the highest quality parts.

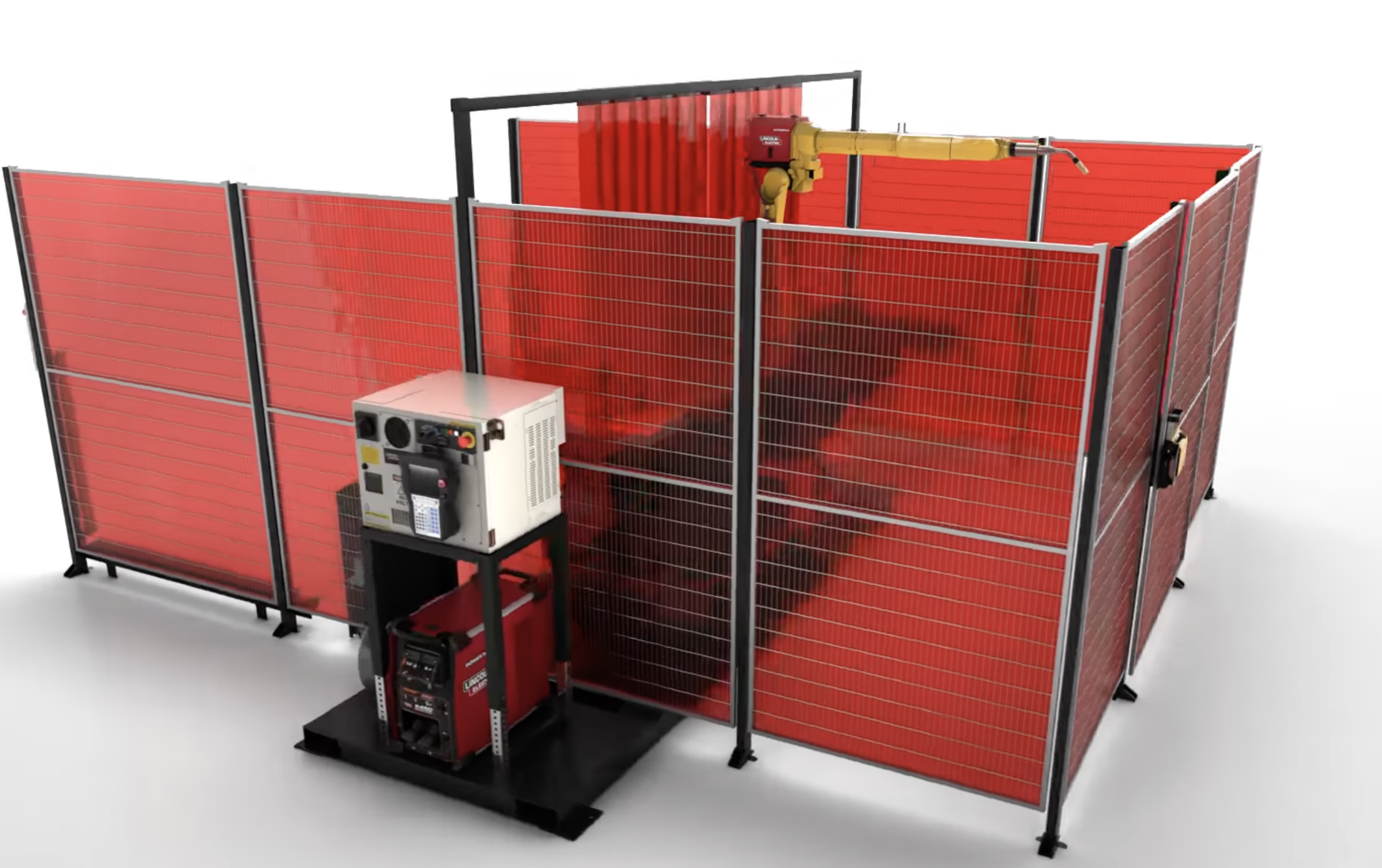

Lincoln Electric Welding Cell

Our Lincoln Electric® FAB-PAK XHS H-FRAME SYSTEM® robotic welder ensures the highest quality welds every single time. This automatic welding system improves productivity, guaranteeing our customers the utmost premier-quality parts in the industry. Excell Industries manufactures completely assembled hydraulic cylinders based on our customer’s specifications.

About Us

PASSION | VISION | IMAGINATION | COMMITMENT

We love what we do and have fun doing it! Mike is the most talented person I have ever met in the manufacturing community. Simply put, he is fearless. He leads from the front and his “can do” attitude and enthusiasm for our trade is contagious. We have seventy‐years of experience combined in the CNC Manufacturing Industry. Our goal is to exceed our customers’ expectations by producing an excellent product on-time every time.

We have invested in the latest machine tool technology, recruited some of the most talented individuals in our industry, and expanded our capabilities in order to become leaders in CNC Manufacturing. Given the opportunity, we can be entrusted to provide innovative solutions that not only meet your requirements, but exceed them.

Mike and Duane

CNC Machining

CNC SUPPORT SOLUTIONS

TURNING & BORING CENTERS

- Doosan Puma GT2600M (3)

- Doosan Puma TT1800SY(4) and TT2500SY Doosan Puma TW2600 GL

- Doosan Puma 2600LM, 3100LM and 5100LMB Doosan Puma 2600LY and 5100LYB Doosan Puma SMX3100ST

- Doosan Puma 2600SY

- Doosan Puma TT2100SYY

- Sierra SKRB Boring Machine

SWISS MACHINES

- Miyano BNX‐51MSY

- Miyano BNA‐42GTY

LINCOLN ELECTRIC WELDING CELL

- Fab-Pak XHS H-Frame System®

AUTOMATED MACHINING CENTERS

- Doosan DNM6700 VMC

- Doosan NHP5000 HMC

- Doosan DVF 5‐Axis VMC

HIGH PRODUCTION CUT‐OFF

- Behringer 321A Band Saw

- Tsune 130GL Cold Saw

- Tsune 160GL Cold Saw

- Sinico Top 2000 CNC Cold Saw

- Hautau RC‐60 Tube Cutoff

SKIVING

- Skiving & Roller Burnishing Machine

Why choose us

flexible solutions for your business needs

TURNING & BORING CENTERS

Our heavy duty PUMA 2600/3100/4100 and 5100 class horizontal turning centers with milling and Y‐axis accommodate small to large workpieces up to 25” in diameter, and 12’ long; making them an ideal solution for the fluid power, mining and oil and gas industry. Our multiple twin‐turret horizontal turning centers are built for mass production of high precision automotive or medical parts, among other industries. They are equipped with live tooling turrets, a Y‐axis and a built‐in design sub‐spindle, fully automated bar‐loader, and integrated part unloader. Finally, our PUMA TW2600GL with an automated loading and unloading gantry system; and our SMX3100ST Multifunction Mill Turn Center with nine axes and outrageous flexibility are difference makers. There is essentially no limit to what we can create.

ROBOTIC WELDING

Our Lincoln Electric® FAB-PAK XHS H-FRAME SYSTEM® robotic welder ensures the highest quality welds every single time. This automatic welding system improves productivity, guaranteeing our customers the utmost premier-quality parts in the industry. Excell Industries manufactures completely assembled hydraulic cylinders based on our customer's specifications.

AUTOMATED MACHINING CENTERS

Our high‐speed vertical and horizontal machining centers are built for massive metal removal. And our NHP5000 and DVF 5‐axis VMC each have automated pallet changing systems. These machines eliminate multiple setups, saving us time and our customers money.

HIGH PRODUCTION CUT‐OFF

We are your source for the high‐volume processing of DOM tubing and solid bar. Our carbide tipped production saws can process incoming raw material up to 12” in diameter and 24’ in length. And our fully automated tube cut‐off system can process 7” tubing complete with ID and OD chamfers, eliminating the majority of secondary operations.

SKIVING

Excell Industries uses the Sierra USA®, the World’s Fastest Skiving & Roller Burnishing machine. With speeds of 4 meters per minute (158” per minute), an 80mm (3.15ʺ) I.D. tube x 1M (39.4ʺ) part length and 2mm (0.040ʺ) stock removal can be skived and roller burnished with one forward pass in 30 seconds. Finishing the inside diameter of a hydraulic cylinder with the most accurate tolerances in the industry will guarantee our customers the highest quality parts.

CNC Machining

QUALITY MANAGEMENT

INSURING THE PRODUCTION AND QUALITY YOUR BUSINESS EXPECTS

We have invested over $2‐million in the last year alone in our quality department and 30,000 sq-ft. facility, which we plan to expand to 90,000 sq‐ft. by 2027. That is in addition to the massive capital investments we have recently made in machinery and equipment to increase our production capability in order to achieve our goal of becoming a premier CNC manufacturing company in the United States.

PRODUCTION CONTROL MANAGEMENT

Production Control Management is held to the highest standards utilizing standard operating procedures. Procedures in place control items for Identification and Traceability of all items. Workflow includes the use of a Router System to show flow of product and guarantee that the highest level of quality standards are maintained. ISO9001‐2015 Certification ensures that all processes are followed throughout all stages of manufacturing.

QUALITY CONTROL MANAGEMENT

Quality Control standards are maintained in our climate controlled Clean Room by utilizing a Mitutoyo Crysta‐Apex V9208 CMM and a Sylvac Scan S145L. Inspection equipment is calibrated by a 17025 accredited laboratory. Nonconformance and Corrective Action trends are periodically reviewed and analyzed by management. Quality Control has a focus on preventing problems form occurring and evaluang risk throughout the entire process.

PRODUCT DISTRIBUTION MANAGEMENT

Product distribution begins with our vendors. Vendors are scrutinized and approved utilizing our strict vendor assessment process. Once items are received, they are brought through our production control management system and securely packaged for shipment. Direct shipping of inventoried products manufactured on behalf of our customers are overseen by our management team and constantly monitored and inspected for on-time delivery and quality.